Packaging inserts play a crucial role in today’s product packaging ecosystem. Inserts can help protect products. This is important for e-commerce businesses, retail brands, and manufacturers of delicate items.

Inserts also improve presentation and overall customer experience. In this guide, we’ll explore the Types of Packaging Inserts, various materials, and how to choose the right option for your brand.

Packaging inserts aren’t just functional; they enhance the unboxing experience. They keep fragile items secure. They help create a professional, organized look inside the box.

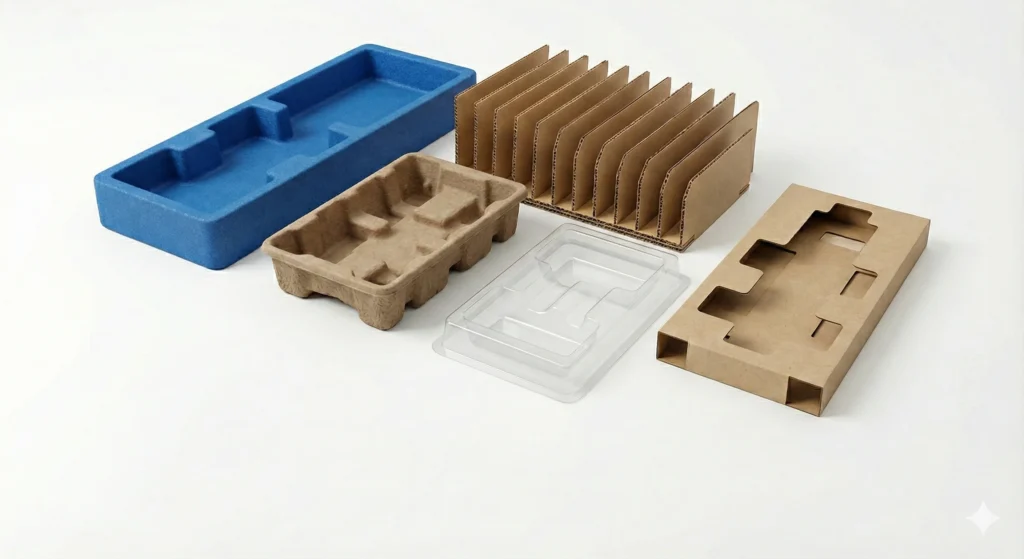

Brands now have many choices for packaging. They can use custom inserts, foam inserts, molded pulp, corrugated cardboard, and die-cut inserts.

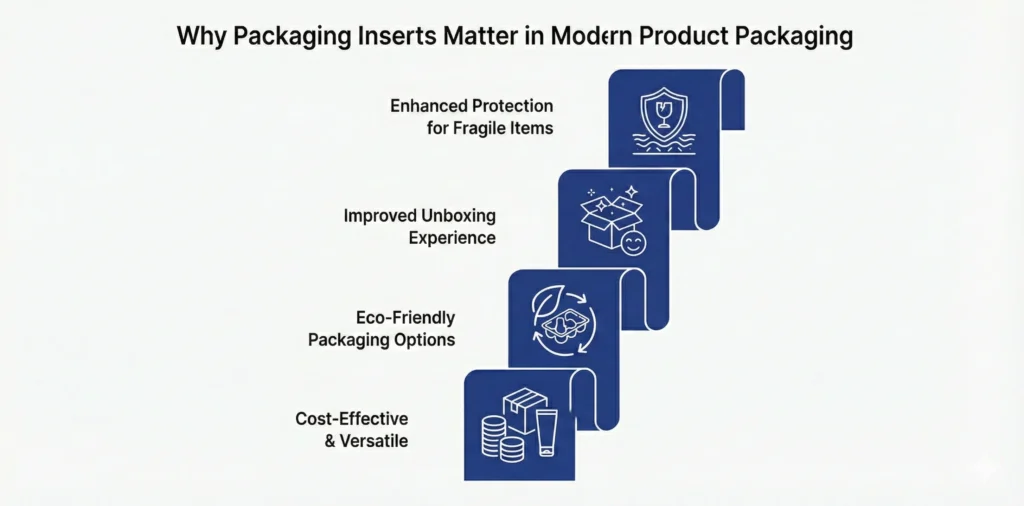

Why Packaging Inserts Matter in Modern Product Packaging

Modern customers expect more than a simple box. They expect an experience, a sense of care that begins the moment they unbox a product. Packaging inserts play a major part in that.

Enhanced Protection for Fragile Items

Products such as electronics, cosmetics, glassware, and ceramics require strong internal support. Packaging inserts prevent movement, absorb impact, and protect fragile items during transit. This reduces the chances of returns, refunds, and customer dissatisfaction.

Improved Unboxing Experience

A well-designed insert makes the product appear organized and premium. Whether it uses custom foam inserts or molded pulp, the right structure elevates your brand’s overall presentation. It makes your brand more memorable and shareable on social media.

Eco-Friendly Packaging Inserts Options

With sustainable packaging on the rise, eco-friendly inserts have become popular alternatives to plastic. These inserts include cardboard, recycled paperboard, and molded pulp. These materials help brands meet environmental goals without compromising product safety.

Cost-Effective & Versatile

Inserts can be tailored to all types of packaging. Whether you need a cost-effective corrugated solution, you can find options for every budget. Whether you need a premium custom box insert for high-end products, you can match any product type.

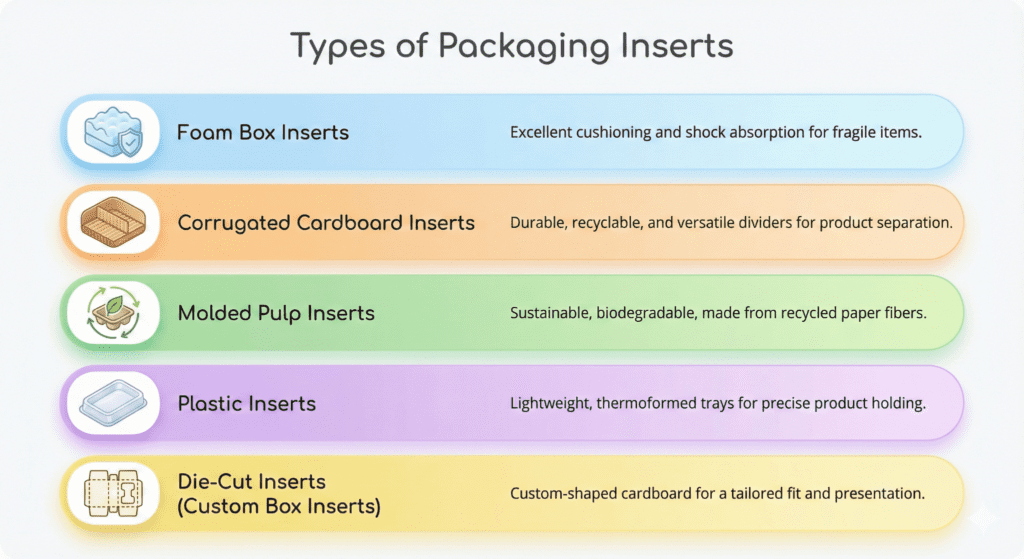

Types of Packaging Inserts

Below are the most common and effective Types of Packaging Inserts used across industries. Each material has its own benefits, ideal use cases, and pricing levels.

Foam Box Packaging Inserts

Foam inserts are ideal for products that require high protection. People often use them for electronics, medical devices, tools, and premium product displays.

Benefits of Foam Packaging Inserts

- High shock absorption

- Excellent for fragile or heavy items

- Available in EVA, PU, PE, and memory foam

- Smooth, professional finish for luxury packaging

When to Use Foam Inserts

Use foam inserts when safety and durability are top priorities. They are also ideal for showcasing high-value products with a premium look.

Corrugated Cardboard Inserts

Corrugated cardboard inserts are one of the most eco-friendly and cost-effective packaging solutions. They are lightweight, customizable, and ideal for everyday product packaging.

Benefits

- 100% recyclable and eco-friendly

- Cost-effective for bulk packaging

- Strong enough to separate multiple items

- Easy to customize using die-cut inserts

Best For

- Beauty products

- Food and bakery items

- Apparel kits

- Home goods

- Lightweight to moderately fragile items

Molded Pulp Inserts

Molded pulp inserts, also called pulp inserts, use recycled paper fibers. They offer strength, shock resistance, and environmental friendliness.

Benefits of Molded Pulp

- Fully biodegradable

- Excellent cushioning for fragile items

- Ideal for eco-conscious brands

- Durable and moisture-resistant

Use Cases

- Electronics

- Cosmetics

- Home appliances

- Bottles and jars

- Sustainable product packaging

If your brand emphasizes sustainability, molded pulp is an excellent choice.

Plastic Inserts

Plastic inserts are durable and long-lasting, making them suitable for products requiring rigid, reusable storage. While less eco-friendly, they offer precision and structure.

Benefits

Waterproof and easy to clean

- Long-lasting

- Ideal for tools, hardware, and accessories

- Highly customizable

Drawbacks

- Less sustainable

- Higher material cost

For brands wanting reusability and rigid protection, plastic inserts can be considered.

Die-Cut Inserts (Custom Box Inserts)

Die-cut inserts are precisely cut to match the exact shape of a product. You can create them using foam, cardboard, corrugated board, or paperboard.

Advantages

- Perfect for premium unboxing

- High level of customization

- Detailed cutouts for product kits

- Professional presentation for retail shelves

Use Cases

- Luxury items

- Cosmetics and beauty sets

- Promotional kits

- Limited edition products

How to Choose the Right Packaging Insert for Your Product

Choosing the right insert involves considering product fragility, branding, sustainability, and budget. Each product has different requirements, so you should select the right material to keep it protected. It also ensures it aligns with your brand’s presentation and environmental goals.

Based on Product Fragility

The level of fragility directly influences which insert material is most suitable. Delicate products need stronger cushioning, while sturdier items only require basic separation. Choosing the right protection level reduces the risk of damage and keeps the product secure during handling and shipping.

High Fragility

- Foam inserts

- Molded pulp inserts

Moderate Fragility

- Corrugated cardboard

- Die-cut cardboard inserts

Low Fragility

- Plastic trays

- Simple cardboard dividers

Based on Branding & Unboxing Experience

Brand presentation plays a major role in customer perception. Inserts help create a clean and intentional product layout, making the unboxing experience memorable. The right insert also enhances the overall aesthetic, helping your packaging feel more premium and share-worthy.

If presentation matters, choose options that enhance product reveal:

- Foam inserts for high-end packaging

- Die-cut inserts for clean, precise placement

- Molded pulp for premium, eco-friendly branding

A good unboxing experience increases customer satisfaction and boosts social media visibility.

Based on Sustainability Goals

Sustainability is becoming a key consideration in packaging decisions. Eco-friendly inserts allow brands to reduce environmental impact while maintaining structure and protection. These materials help communicate your commitment to responsible packaging without compromising quality.

Eco-friendly insert materials include:

- Molded pulp

- Recycled cardboard

- Corrugated board

- Recycled paperboard

These options reduce plastic use without compromising protection.

Based on Budget & Cost-Effectiveness

Budget often determines which insert is the most practical choice. Some materials provide strong protection at a lower cost. Others deliver a premium feel at a higher price point. Evaluating product value, shipping distance, and required durability helps you select the most efficient option.

- Most cost-effective: cardboard & corrugated

- Mid-range: molded pulp

- High-end: foam & custom die-cut inserts

Consider your product value, shipping method, and required protection.

When to Use Packaging Inserts (Practical Scenarios)

Packaging inserts play a vital role in ensuring products stay safe, organized, and beautifully presented. Whether you ship items, sell multi-product kits, or enhance your brand’s unboxing experience, inserts provide structure. They also provide protection and visual appeal. Below are the most common scenarios where inserts become essential for both function and presentation.

Product Kits & Bundles

Packaging inserts keep multiple items separated and neatly arranged, making the packaging more professional and organized. They help prevent items from touching or damaging each other, especially in multi-piece sets. Inserts also make the unboxing process smoother by guiding customers through each component inside the kit.

Fragile Items

If your product is breakable, inserts are not optional; they are essential. Foam, molded pulp, and die-cut cardboard help prevent movement and impact damage. These materials provide cushioning during transit, reducing the risk of cracks, dents, or deformation. Using the right insert also reassures customers that your brand prioritizes product safety.

E-commerce Shipping

Packaging inserts reduce returns because of damage and improve customer trust in your shipping quality. They keep products firmly in place, minimizing the shock and vibration that occur during long-distance deliveries. For e-commerce brands, this means fewer complaints, better reviews, and a more consistent customer experience.

Creating a Premium Unboxing Experience

Inserts help position your brand as premium by controlling how each item is presented inside the box. They create a clean, intentional layout that enhances product reveal and elevates perceived value. From custom foam inserts to precisely cut cardboard trays, the right insert design enhances unboxing. It makes your unboxing feel memorable and share-worthy.

Read More: How to Make Custom Packaging Boxes: A Guide for Your Brand

Advantages of Using Packaging Inserts

- Improve product safety

- Enhance visual presentation

- Support eco-friendly packaging goals

- Boost social media sharing

- Add space for manuals, discount codes, and marketing inserts

- Elevate the unboxing experience

- Help reduce shipping damage and return rates

Packaging inserts are a great way to add functionality and branding value to your packaging strategy.

Custom Packaging Inserts: When to Go Fully Custom

- Your product has a unique shape

- You sell luxury items

- You want full brand consistency

- You need a premium unboxing experience

- You require precise placement for multiple pieces

Custom box inserts ensure every product sits perfectly inside the box, improving both protection and presentation.

Frequently Asked Questions

- What type of packaging insert is best for fragile items?

Foam and molded pulp inserts are ideal due to their shock-absorbing and structural strength.

- Are foam inserts eco-friendly?

Standard foam is not, but recycled or biodegradable foam options exist.

- Do molded pulp inserts offer durability?

Yes, molded pulp inserts are strong, protective, and used widely in electronics and home appliances.

- How do packaging inserts improve the unboxing experience?

Inserts organize items, present them neatly, and add a premium feel.

- What is the most cost-effective insert material?

Corrugated cardboard inserts are the most budget-friendly and eco-conscious option.