The snack aisle is no longer just a battle for taste buds; it is a battle for the planet. As single-use plastics face unprecedented scrutiny, the transition to sustainable snack packaging has become the primary differentiator for high-growth snack brands. To remain competitive, companies must pivot from the traditional “linear” model toward a robust circular economy.

Continuing with conventional plastic packaging is becoming a financial liability. With increasing plastic taxes and the rising cost of virgin polymers, the move toward eco-friendly products is a strategic hedge against future market volatility. By 2026, the global snack packaging market is projected to surpass $24.4 billion, with the fastest-growing segments being those that successfully integrate sustainable packaging solutions.

Deciphering Consumer Demands: What Conscious Consumers Really Want

Modern conscious consumers are savvy. They look past the “green” aesthetics and demand technical transparency. They are seeking products that are sustainably packaged from the core out, not just in their marketing materials.

The Psychology of the “Eco-Purchase”

Shoppers are prioritizing brands that provide clear end-of-life instructions. To understand the shift in the market, consider the following data on consumer sentiment and willingness to invest in sustainability.

2025-2026 Consumer Sentiment Analysis

| Metric | Percentage of Consumers | Business Impact |

| Likely to buy from brands with eco-packaging | 90% | High conversion potential |

| Willing to pay a premium (10-20%) for sustainability | 43% | Offset for higher material costs |

| Deliberately chose sustainable packaging recently | 54% | Established market behavior |

| Expected brands to offer sustainable options by 2026 | 69% | Baseline market expectation |

Engineering the Future: High-Performance Sustainable Packaging Solutions

The biggest barrier to entry for many brands has been the “performance gap.” However, science has finally caught up to the demand, allowing snack brands to switch to sustainable snack formats without losing product integrity.

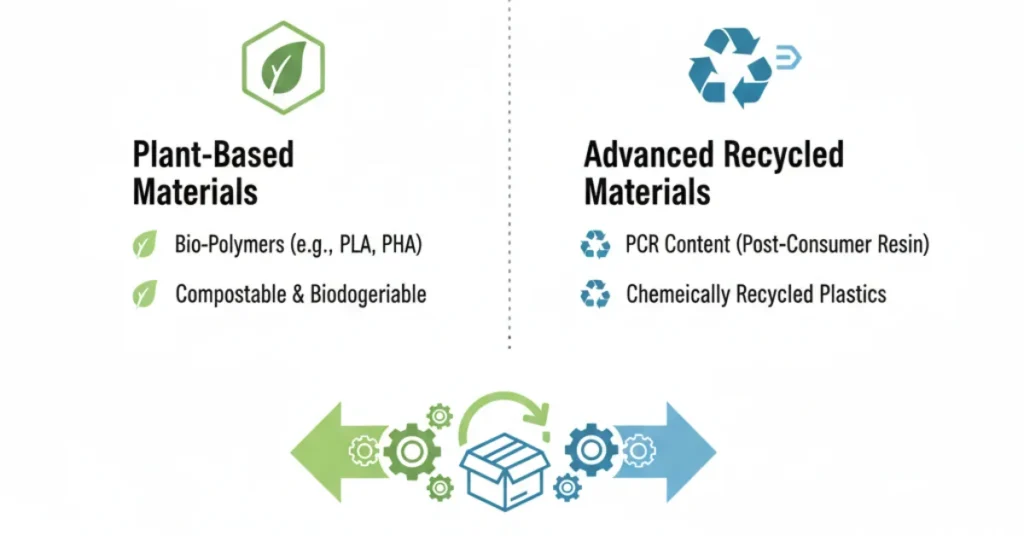

Plant-Based Materials vs. Advanced Recycled Materials

To outrank competitors, brands must choose the right substrate for their specific product:

- Bio-Polymers: Utilizing plant-based materials like PLA (Polylactic Acid) and PHA to offer fully compostable options.

- PCR Content: Integrating recycled material to decrease reliance on fossil fuels while maintaining the durability of traditional plastics.

Solving the “Shelf Life” Paradox

One of the primary concerns in food packaging is the preservation of freshness. Advanced sustainable snack packaging now incorporates multi-layer technology that protects against oxygen and moisture.

Performance Comparison: Sustainable vs. Conventional Materials

| Material Type | Oxygen Transmission Rate (OTR) | Moisture Barrier (WVTR) | Carbon Footprint Reduction |

| Standard Plastic (PET/PE) | 0.05 – 0.1 | 0.1 – 0.2 | Baseline |

| High-Barrier Compostable (PLA) | 0.08 – 0.15 | 0.3 – 0.5 | 25% – 40% Reduction |

| Recycled Content (PCR Plastic) | 0.05 – 0.1 | 0.1 – 0.2 | 30% – 50% Reduction |

| Bio-based Coated Paper | 1.0 – 5.0 | 5.0 – 10.0 | 60% – 75% Reduction |

How to Reduce Environmental Impact Without Losing Margin

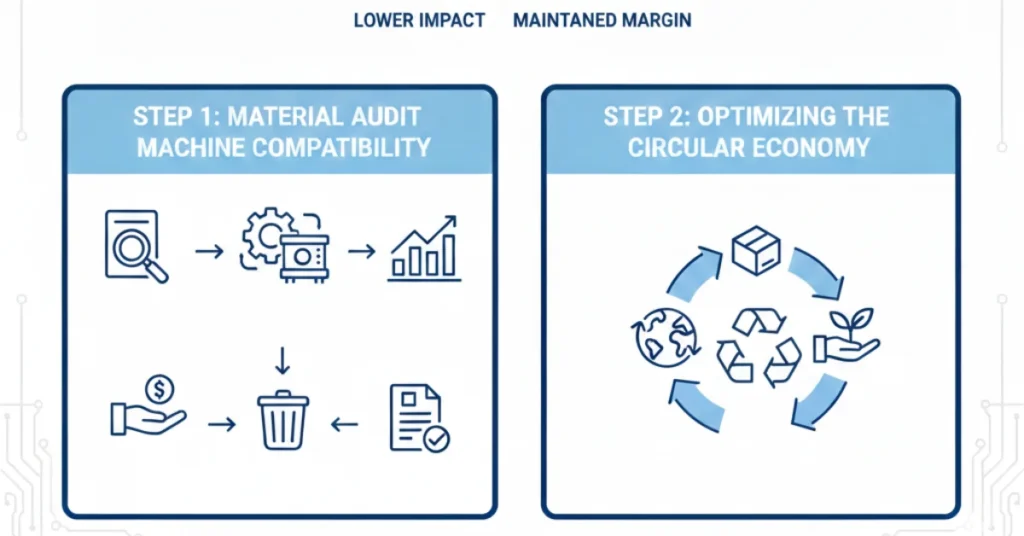

The transition requires a strategic roadmap. It isn’t just about changing materials; it’s about optimizing the entire supply chain to lower your carbon footprint.

Read More: Attapack: Order Custom Stickers and Labels

Step 1: Material Audit and Machine Compatibility

Before you switch to sustainable snack options, test how these new packaging materials perform on your existing machinery. Modern sustainable films are designed to be “drop-in” ready, often requiring only minor heat-sealing adjustments.

Step 2: Optimizing the Circular Economy

Focus on reducing packaging waste at the source. Lightweighting and “right-sizing” your pouches can lead to significant savings in logistics and material costs, often offsetting the premium price of bio-materials.

Operational Impact of Sustainable Transition

| Strategy | Expected Outcome | Statistical Analysis |

| Lightweighting | Reduced material usage | Up to 15% lower shipping costs |

| High-Barrier Bio-Films | Extended shelf life | 40% reduction in food waste |

| Post-Consumer Recycled (PCR) | Supply chain stability | 20% reduction in fossil fuel reliance |

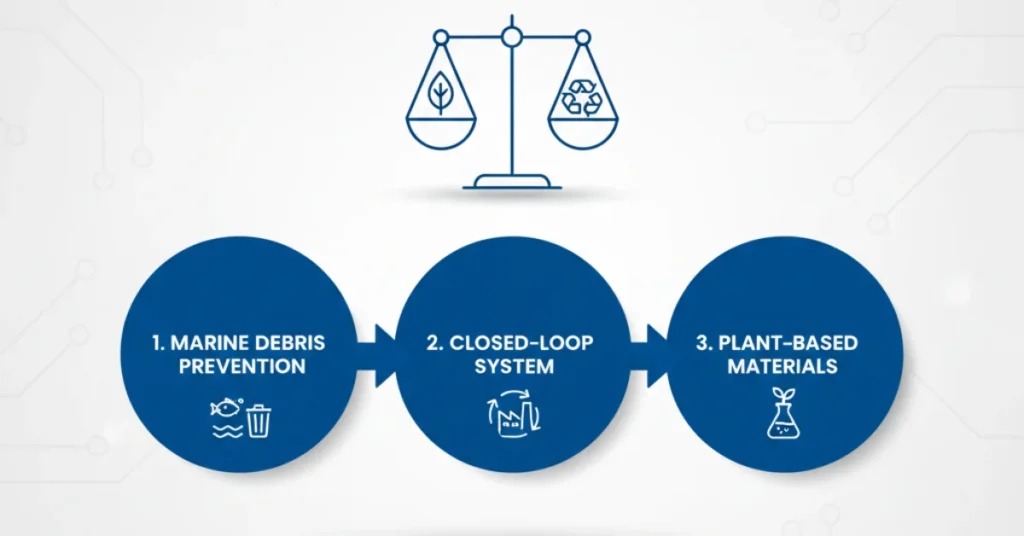

Overcoming the Science of Climate Change through Better Design

The food industry is a major contributor to global emissions. By choosing sustainable packaging solutions, brands directly contribute to the science-based targets required to mitigate climate change. This involves:

- Ensuring packaging doesn’t end up as marine debris.

- Supporting a closed-loop system where waste becomes a resource.

- Utilizing plant-based materials that act as carbon-neutral feedstock.

Read More: Order custom luxury corporate gift boxes – Attapack

Conclusion

The future of snacking is transparent, ethical, and efficient. By prioritizing sustainable snack packaging, you aren’t just meeting a trend; you are establishing your brand as a leader in a world that no longer accepts plastic as the default.

Partner with the Experts in Eco-Innovation

Navigating the complexities of the green market requires a partner who understands both the chemistry and the commerce of sustainability. At AttaPack, we provide the premium sustainable snack packaging solutions that modern snack brands need to thrive.

Whether you are looking for high-barrier plant-based materials or looking to integrate recycled material into your lineup, we offer the technical expertise to help you reduce environmental impact without compromising on shelf life. Experience the perfect blend of performance and purpose. Visit AttaPack today to revolutionize your packaging strategy and meet the growing consumer demands for a cleaner, greener world.